Description

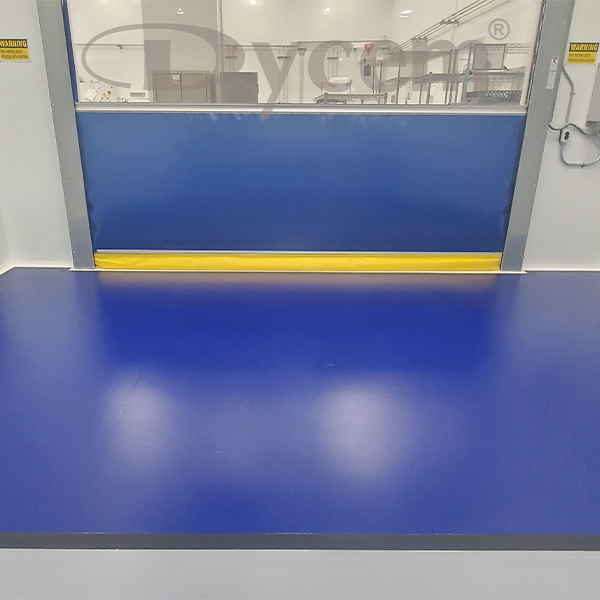

Dycem® WorkZone Antimicrobial Flooring

WorkZone is the ONLY effective contamination control mat or flooring for areas subject to heavy wheeled traffic. It is specially designed to attract, collect and retain contamination from the wheels of forklifts, pallet trucks and large carts up to 1280lb/psi, preventing unwanted particles from entering critical areas. The flooring can be installed into a variety of heavy-duty areas and is available with a low profile, food-grade stainless steel edging option or a heavy duty aluminum edging system. This is a permanently installed solution with a product life cycle between 3-5 years. Available color to highlight the contamination is Charcoal or if you would like to hide the contamination, a Granite color scheme is an option.

Please call or email for pricing and further information

On-site surveys are available, call or email to schedule yours today! You can also send us your floorplans which would allows us to put together a visual representation and recommendation.

KEY BENEFITS

– ONLY effective solution for wheeled traffic

– Reduced floor (up to 99.9%) and air particulate (up to 75%) counts in controlled or critical areas

– Long lasting, cost effective solution compared with peel-off mats and other alternatives

– Reduced microbial counts due to Biomaster, a high performance anti-microbial additive in all Dycem products

– Easy to clean, maintain, and incorporate into existing Standard Operating Procedures (SOP’s)

KEY FEATURES

– Can be installed as a standard mat or fully customized for areas that are complex in shape and construction

– Ideal for inlaid or wall-to-wall flooring installations

– Available in a range of colors for color-coding critical locations and providing clear demarcation between clean and dirty areas

– Product life expectancy of 3-5 years (if maintained correctly as per manufacturer’s instructions)

– Protected by a standard 12-month warranty from date of installation

WHERE TO USE WORKZONE

– All material entrances to critical areas to prevent ingress of contamination from wheels

– All material exits to prevent contamination leaving the critical area

– Inside airlocks, warehouses, and product transfer areas to control and retain contamination

– In hallways to prevent cross contamination

– Inside the critical area adjacent to critical products and processes